The oil and gas sector, being a cornerstone of the global economy, relies heavily on sophisticated machinery and equipment.

Even a minor malfunction in a single component can bring the entire production process to a standstill, resulting in losses worth millions of dollars. Additionally, these facilities usually operate around the clock, and just one hour of downtime can cause substantial financial setbacks.

For this reason, ensuring the availability and proper maintenance of critical spare parts for oil and gas machinery is of utmost importance.

In this article, we highlight five key components whose failure could lead to a complete halt in production and significant economic losses.

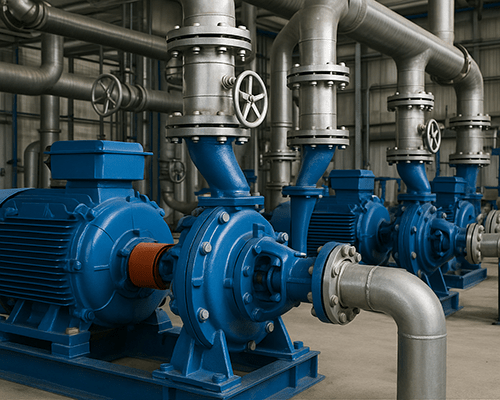

The Function of Pumps in the Oil & Gas Sector

Pumps play a crucial role in moving crude oil, natural gas, and other process fluids through pipelines.

If pumps fail to operate correctly, the flow of fluids stops, bringing production to a standstill.

Frequent Pump Problems

The Value of Genuine Spare Parts

Relying on low-quality spare parts for pump maintenance raises the likelihood of breakdowns and production delays.

Using authentic spare parts for industrial pumps enhances equipment reliability and helps minimize unexpected expenses.

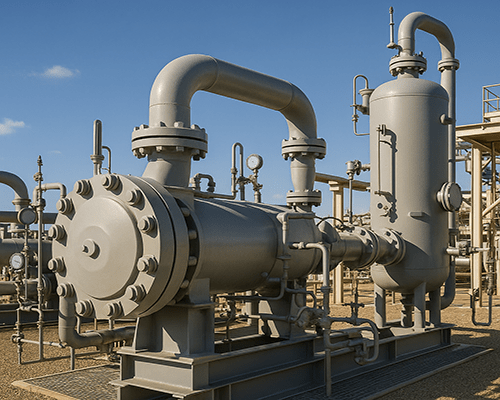

Why Compressors Are Essential

In the oil and gas sector, compressors play a crucial role in compressing gases, a necessary step for transporting gas through extensive pipelines or supplying it to subsequent processes.

A malfunctioning compressor can bring an entire processing unit to a halt.

Beyond stopping production, compressor malfunctions can increase pressure and raise the risk of explosions.

Such failures not only result in financial losses but also present serious safety hazards.

Ensuring the timely availability of genuine compressor spare parts is an investment in both operational efficiency and safety.

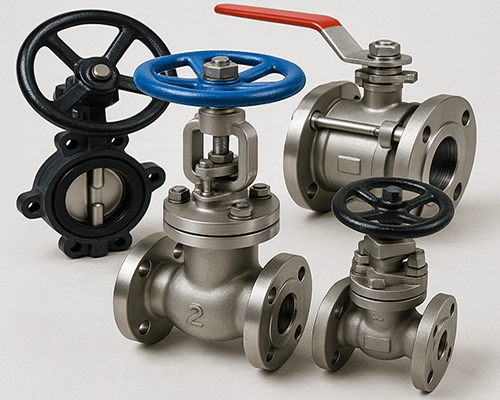

The Function of Valves in Oil and Gas Pipelines

Industrial valves play a vital role in regulating the flow of oil and gas. A malfunctioning valve can lead to significant leaks, waste of valuable resources, and even large-scale fires.

Typical Valve Spare Parts

The Necessity of Prompt Spare Part Supply

In drilling and refining operations, spare parts for equipment, particularly valves, must always be accessible. Even the absence of a small component, such as an O-ring, can stop the entire production process.

Why Turbines Are Crucial

Gas turbines are essential for generating power and electricity within refineries.

Without them, production operations effectively come to a standstill.

Impact of Turbine Failures

Each hour of downtime for a gas turbine can lead to losses of hundreds of thousands of dollars.

Hence, preventive maintenance and timely availability of turbine spare parts are essential requirements.

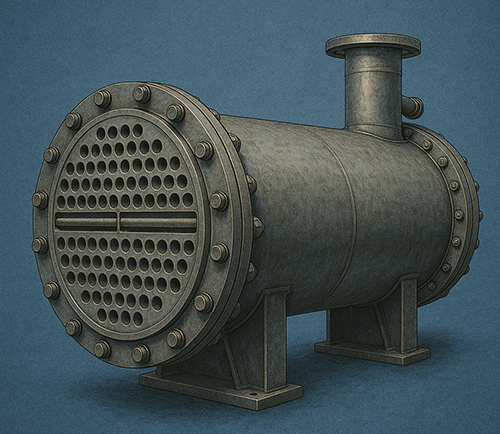

The Function of Heat Exchangers

Heat exchangers play a critical role in transferring heat during refinery processes.

Without their proper operation, the quality of the final product can be severely affected, and production may even come to a halt.

The Importance of Preventive Maintenance

Failure to replace tubes and gaskets on time can lead to leaks and decreased efficiency.

This not only results in financial losses but also poses significant safety hazards.