The steel industry stands as a vital pillar of worldwide manufacturing, underpinning key sectors such as construction, transportation, automotive, industrial machinery, and more.

It encompasses the entire process of producing steel and steel products from primary raw materials like iron ore and coal.

The steel industry includes all activities involved in transforming raw iron ore into steel. This involves processes such as extraction, refining in various types of furnaces, casting, rolling, and finishing operations to produce steel products suitable for a wide range of applications.

1. Steel Production

Steel production involves converting iron ore into steel through methods like blast furnaces or electric arc furnaces. Steel, an alloy of iron and carbon, is prized for its exceptional strength and mechanical properties and serves as a fundamental raw material for numerous industries.

2. Construction Sector

Steel plays a crucial role in construction, being a primary material in bridges, buildings, roads, and infrastructure. Its durability, strength, and flexibility make it indispensable in creating safe and long-lasting structures.

3. Automotive Industry

The automotive sector relies heavily on steel for manufacturing vehicle bodies, chassis, and internal parts. Steel’s combination of strength and ductility enhances both safety and performance in vehicles.

4. Machinery and Equipment Manufacturing

Steel supplies the foundation for producing industrial machines, manufacturing tools, and heavy equipment. Its quality and precision make it essential for building durable and reliable components.

5. Pipe and Profile Production

Steel is also vital in manufacturing pipes and structural profiles used across various industries, including oil and gas, water supply, and more.

1. Iron Ore Extraction and Processing

Iron ore, the primary raw material for steel, is mined and then transported to melting facilities.

2. Blast Furnace

This traditional method converts iron ore into molten iron by removing impurities before refining it into steel.

3. Electric Arc Furnace (EAF)

An eco-friendly technique that melts recycled steel scrap, reducing reliance on raw materials and energy consumption.

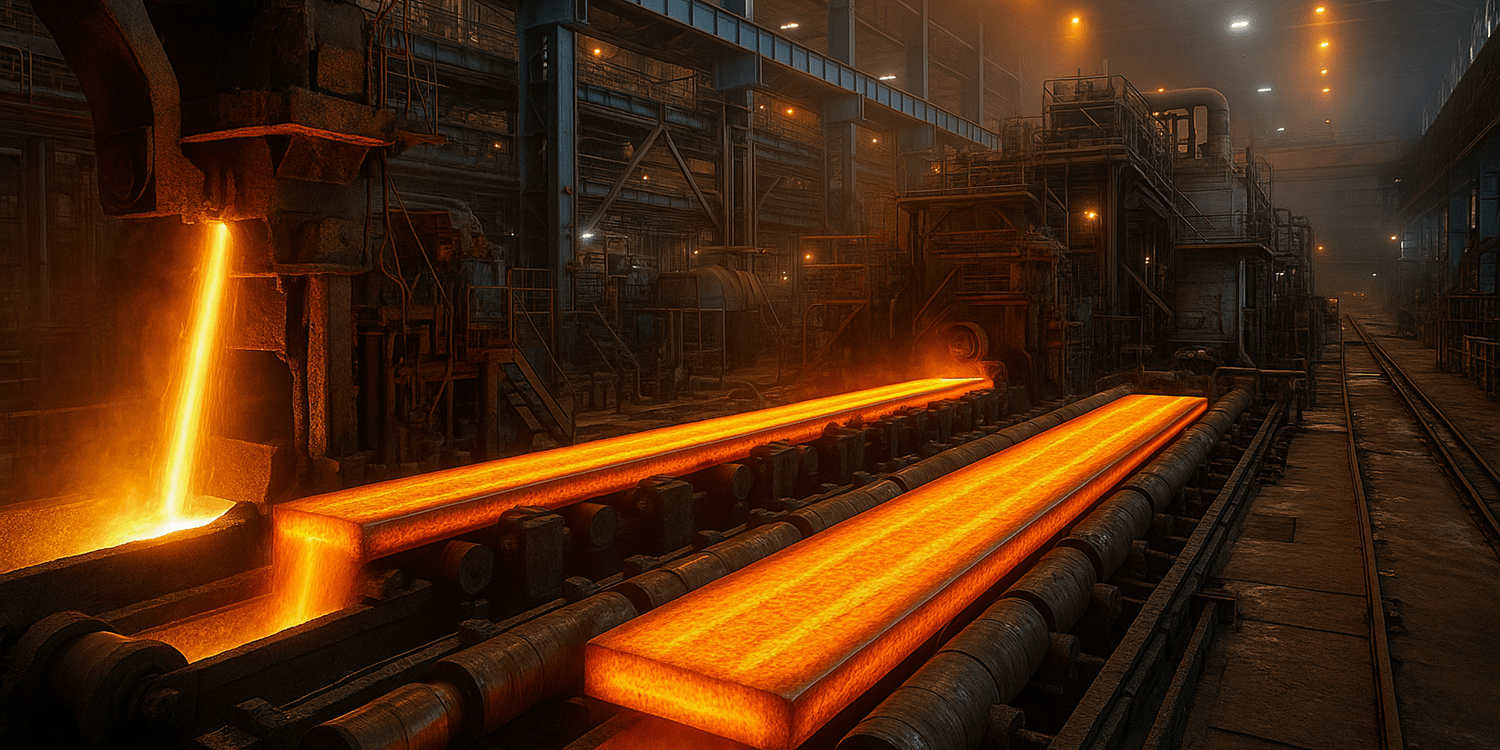

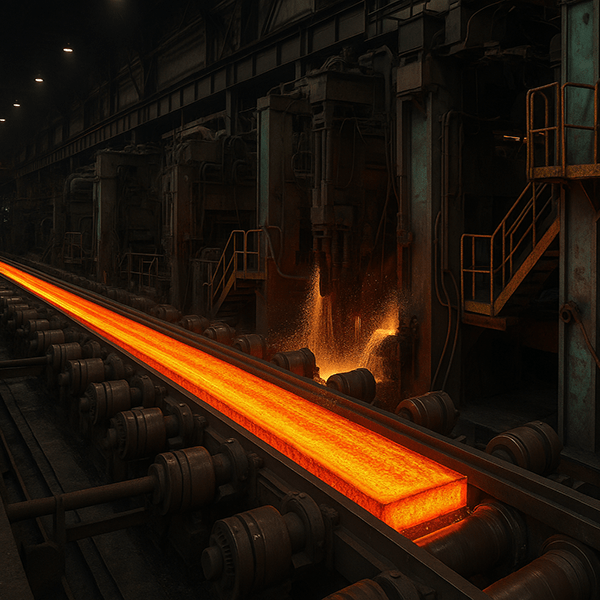

4. Rolling

Molten steel is shaped into sheets, bars, pipes, beams, and other forms through rolling.

5. Casting and Forming

Steel is cast and formed into specific shapes for a variety of industrial applications.

The steel industry is one of the world’s largest and most impactful economic sectors.

It supplies critical materials for infrastructure development, transportation, and industrial machinery, driving growth across numerous fields.

Additionally, it generates significant employment opportunities and contributes substantially to national GDP in many countries.

A strong steel industry serves as the backbone of industrial progress, directly supporting a country’s economic development and technological advancement.