Gulf Land Integrated Investment Solutions & Equipment

Refractory Mortar and Ramming

Gulf Land Integrated Investment Co provides high-quality refractory mortar and ramming, designed for durability and practical use. These materials offer excellent adhesion, withstand extreme temperatures, and ensure long-lasting performance, making them ideal for constructing and repairing furnaces and thermal equipment across a variety of industrial sectors.

Description

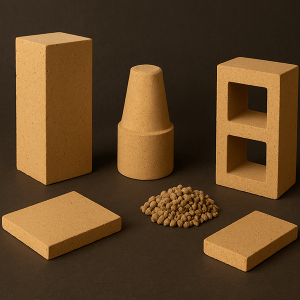

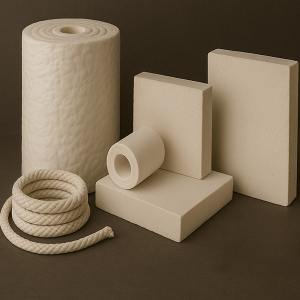

Refractory Mortar and Ramming Materials

Refractory mortar and ramming mixes are advanced solutions engineered for extreme thermal applications in heavy industries. Formulated with high-quality minerals such as alumina, silica, and magnesia, these materials deliver outstanding protection against intense heat, chemical reactions, and mechanical stress. While refractory mortar is mainly applied for bonding and repairing refractory bricks, ramming compounds provide a moldable and durable lining option for industrial furnaces and kilns.

Main Advantages

- High resistance to elevated temperatures and thermal shock

- Strong bonding capability for secure installation and maintenance of refractory systems

- Excellent protection against corrosion, slag, and chemical attack

- Flexible and easy to shape or adjust during application

- Long-lasting performance in demanding industrial environments

Industrial Applications

- Bonding, sealing, and repairing refractory bricks in furnaces, boilers, and kilns

- Lining floors, walls, and critical sections of steel, foundry, and metallurgical furnaces

- Rehabilitation of deteriorated refractory areas to restore efficiency

- Widely used in cement production, glass manufacturing, petrochemical plants, and metallurgy

- Enhances the service life of thermal processing units and industrial equipment